MODULAR DOCKING TRAIN SYSTEM

KEY FEATURES:

- Modular in Design

- Robust with Minimal Moving Parts

- Productivity Through Innovation

- Safety and Ergonomics as Standard

- Efficiency with flexibility

MODULAR DOCKING TRAIN SYSTEM

KEY FEATURES:

- Modular in Design

- Robust with Minimal Moving Parts

- Productivity Through Innovation

- Safety and Ergonomics as Standard

- Efficiency with flexibility

GET IN TOUCH! +44 (0)161 903 9422

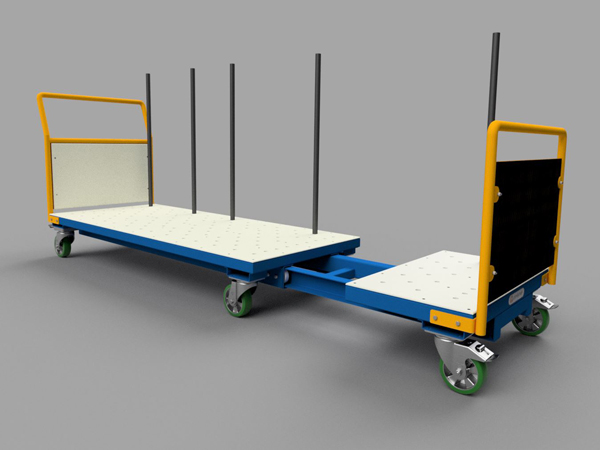

In any industry, regardless of its size or function, efficient production is highly dependent on perfectly coordinated processes and timely supply of materials and products. This is where material flow, both inbound and outbound, plays a critical role in driving efficiency and profitability. The Modular Docking Train is a custom-made solution designed to cater to specific customer requirements, ensuring just-in-time delivery of materials, whether they are internally or externally sourced within the customer’s site.

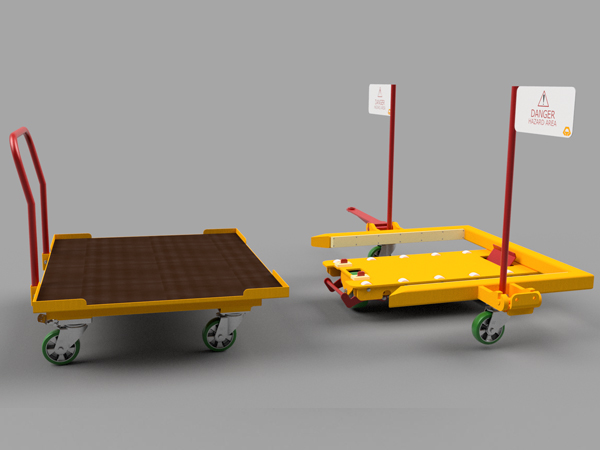

The modular docking train is highly versatile and can be towed using a pedestrian mover or a ride-on tow tractor. With its modular design, units can be interchanged to suit the load. The overall efficiency of the modular docking train is derived from its flexibility in material flow, increased volumes per operative, safety for personnel, and condition of materials at the point of use. Whether the products are palletized, in tote boxes, or individually packed, the system can be designed to meet the customer’s unique requirements.

With its flexibility, robustness, and excellent turning circles and manoeuvrability, the modular docking train can be a valuable addition to any workplace.

CHASSIS

The durable chassis design of the docking system enables the load locking pins to be automatically operated with a secondary locking mechanism, ensuring added security and reliability.

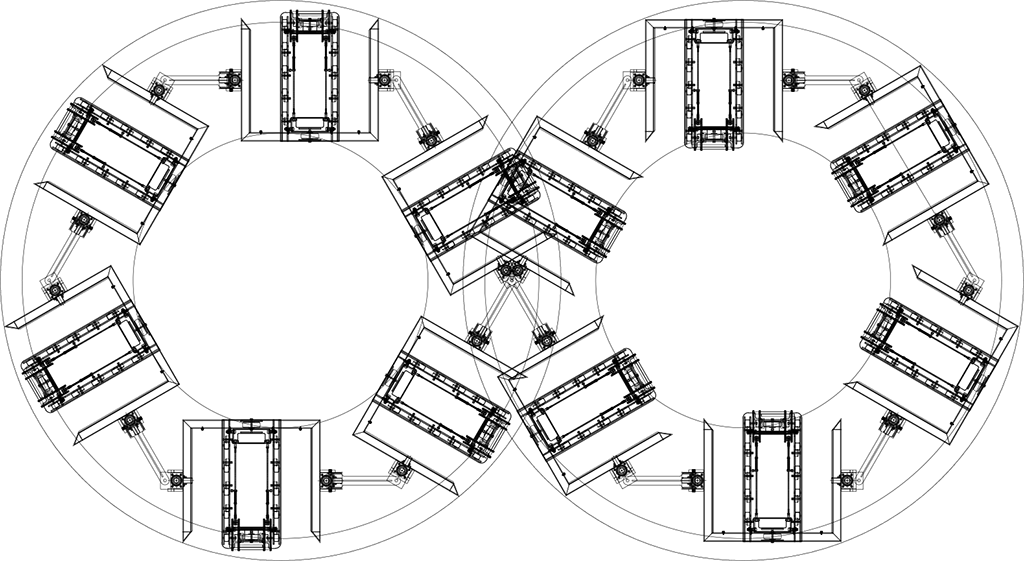

STEERING

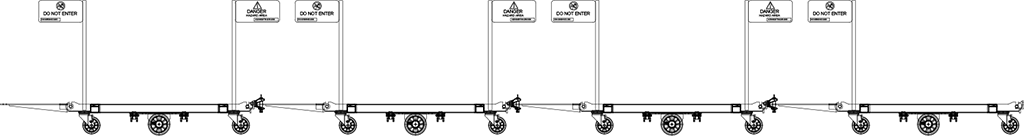

The use of multiple units in a train system allows for near-perfect tracking, which results in exceptional manoeuvrability and tight turning.

The only limiting factor is the working environment, which may restrict the number of units that can be used in the train system.

WHEELS & TYRES

Castor Wheel and Tyre Selection

The selection of castor wheels and train systems depends on the specific working environment and usage, taking into consideration various factors such as:

- Capacity

- Speed

- Rolling resistance

- Ground conditions

- Ride quality

- Non marking

- economics

- Load height / centre of gravity

- Noise reduction

All above available as anti static or electrically conductive if required.

FINISH

At Alexander Trailers, we understand that the finish of your trailer is important, which is why we offer a range of options to suit your individual requirements. Whether you need a specific colour or finish for corporate branding or to meet health and safety legislation, we can accommodate your needs.

Our range of finishes includes:

- Powder coating

- Wet spray standard finish

- Galvanizing

- Customer specified finishes, including offshore or specialised paint systems.

In addition, we can obtain ATEX certification for specific use if required. Whatever your needs, we can work with you to ensure your trailer has the perfect finish.

Industrial Trailers

Alexander Trailers specialise in the bespoke build of trailers for a variety of industrial uses

Our enclosed trailers, including curtain-sided, cage, box, and tank trailers, offer a secure and versatile solution for trans…

Platform trailers are widely used across various industries to transport goods and equipment within and outside…

Our castor steered trailer decks are specifically designed and manufactured to secure even the most awkward…

Castor steer trolleys can be operated manually or towed by a motor mover or tow tractor, either individually or in train…

A wide range of wheelie bin and cage trailers that are tailored to meet the demands of any type of load…

The modular docking train is highly versatile and can be towed using a pedestrian mover or a ride-on tow…

GET IN TOUCH! +44 (0)161 903 9422